Reliable Source for Precision Machinery

QZSD Machinery, a trusted manufacturer based in Quanzhou, China, specializes in precision parts for global clients. With our state-of-the-art factory, we deliver custom-engineered solutions that meet international quality standards while ensuring competitive pricing and reliable delivery.

End-to-End Customization Process

We offer a seamless end-to-end customization process, transforming your specifications into precision-engineered parts through consultation, design, manufacturing, quality testing, and worldwide delivery.

Initial Quote Consultation

Our process begins with a thorough consultation to understand your specific requirements, usage conditions, and quantity needs to ensure we capture all essential details for successful production.

Parts Design Review

Our engineering team reviews your specifications and creates detailed drawings, suggesting optimal materials and processes to ensure cost-efficiency and compliance with international standards.

Prototype Development

We create precise prototypes for your approval using our advanced manufacturing technology, allowing you to inspect and test the design before committing to full-scale production.

Production Planning

Before mass production, we provide final customization samples and detailed specifications for your confirmation, ensuring every aspect meets your requirements and quality standards.

Quality Testing

Every manufactured part undergoes rigorous multi-stage quality testing including dimensional verification, material composition analysis, and performance testing to guarantee consistent quality.

Final Inspection & Delivery

We handle all logistics aspects including secure packaging, export documentation, customs clearance, and reliable shipping arrangements to deliver your custom parts safely and punctually to your facility.

Why Choose Us

By combining advanced manufacturing technology, strict quality control, competitive pricing and reliable delivery, we provide superior precision parts that meet your exact specifications.

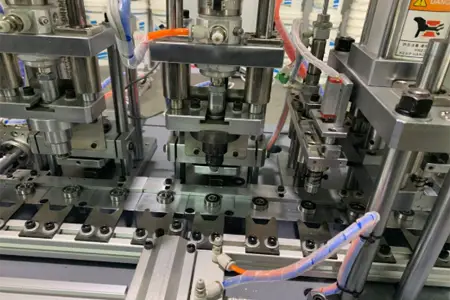

Advanced Manufacturing Technology

Our state-of-the-art facility utilizes precision CNC machinery, automated quality inspection systems, and the latest manufacturing technologies to produce parts with exceptional accuracy, consistency, and durability that meet or exceed industry standards.

Quality Assurance System

Every product undergoes rigorous multi-stage quality testing including dimensional verification, material composition analysis, and performance evaluation to ensure zero defects and complete compliance with international manufacturing standards.

Competitive Global Pricing

We offer unparalleled value through the optimisation of production processes, the strategic procurement of materials, and manufacturing efficiency, while maintaining the highest quality standards to assist in the reduction of your total cost of ownership.

Custom Design Capabilities

Our skilled engineering team can transform your concepts into manufacturable designs, offering expert material selection, tolerance optimization, and production solutions that perfectly match your functional requirements and budget constraints.

Experienced Industry Experts

With over 23 years of specialized manufacturing experience, our technical team possesses deep industry knowledge and problem-solving capabilities to address complex engineering challenges and deliver optimal solutions for your specific applications.

Reliable On-time Delivery

We maintain strict production schedules, efficient inventory management, and established relationships with global logistics providers to ensure your orders arrive exactly when promised, helping you maintain your production timelines.

Modern Manufacturing Facility

Our modern manufacturing facility in Quanzhou combines advanced CNC equipment, automated quality control systems, and skilled technicians to ensure precise, consistent production of high-quality parts.

Sustainable Production Practices

Our Quanzhou facility implements energy-efficient manufacturing processes and waste reduction systems that minimize environmental impact. Solar panels supplement our power needs while intelligent machinery scheduling optimizes energy consumption. These sustainable practices reduce production costs while maintaining our commitment to responsible manufacturing.

Digital Integration & Smart Factory

QZSD’s manufacturing center utilizes IoT-connected machinery, real-time production monitoring, and digital workflow management. This integration allows us to track each part’s progress, predict maintenance needs, and address production variations immediately.

Research & Development Center

Adjacent to our production floor sits our dedicated R&D center where engineers test new materials, prototype designs, and optimize manufacturing processes. This continuous improvement hub helps develop proprietary techniques that enhance quality and efficiency.

Work Environment

Our modern, well-equipped factory maintains strict quality control standards while providing a safe, collaborative space where skilled technicians work with precision machinery to craft reliable parts.

Manufacturing Information Guide

Optimise your custom parts projects with QZSD Machinery by accessing comprehensive manufacturing resources covering material selection, design specifications, quality standards and production processes.

To process your custom order efficiently, we need detailed specifications including technical drawings (CAD files preferred), material requirements, surface treatment preferences, quantity needed, application details, tolerance requirements, and delivery timeline. Providing clear information helps us understand your exact needs and reduces back-and-forth communication. For complex customizations, our engineering team can schedule a consultation to discuss your project requirements in detail and suggest optimal manufacturing approaches.

Our minimum order quantity varies based on part complexity, material type, and manufacturing process. For standard custom bearings, bolts, and nuts, we typically require an MOQ of 200 pieces. For highly specialized components, we may accept smaller quantities. Contact our sales team with your specifications for precise MOQ information related to your specific requirements.

The customization timeline depends on design complexity, material availability, and order volume. After receiving complete specifications, we provide a 3-5 day turnaround for quotes. Production lead times range from 15-30 days for standard customizations and 30-45 days for complex projects. Rush orders may be accommodated based on our production schedule and capacity.

Yes, we offer sample production before full-scale manufacturing. Sample costs vary based on complexity and are often credited toward your final order. Most custom samples are ready within 7-12 days after design approval. We encourage sample testing to verify fit, function, and quality before proceeding with large production runs.

We work with a wide range of materials including carbon steel, stainless steel (304, 316, 440C), alloy steel, brass, bronze, aluminum alloys, and various engineering plastics. All materials meet international quality standards. Our engineering team can recommend the most suitable material based on your application requirements, environmental conditions, and budget constraints.

Yes, all custom parts undergo rigorous quality testing before shipment. We provide material certificates, dimensional inspection reports, and when requested, specific testing documentation such as hardness, tensile strength, or chemical composition analysis. Our facility maintains ISO 9001 certification, and we can meet industry-specific standards based on your requirements.

Yes, we regularly modify standard bearings, bolts, and nuts to meet specialized needs. Common modifications include dimensional adjustments, material upgrades, surface treatments, tolerance improvements, and adding features like grooves or holes. This approach often saves time and cost compared to fully custom designs while still meeting your specific requirements.

Pricing for custom parts is determined by material costs, manufacturing complexity, volume, surface treatments, and quality requirements. We provide transparent quotes with no hidden fees. For long-term partnerships, we offer volume discounts and can develop cost-reduction strategies. All quotes include material, labor, quality control, and basic packaging costs.

Testimonials

Find out why our global clients trust us with their precision parts requirements by reading authentic feedback about our quality, reliability, customisation capabilities and exceptional service.

Working with QZSD Machinery transformed our production line efficiency. Their custom stainless steel bearings outlasted our previous supplier’s by 40%. We initially ordered 2,000 units for our food processing equipment, and have since placed three additional orders. Their engineering team suggested material modifications that solved our corrosion issues completely.

QZSD provided custom high-tensile bolts for our construction equipment that withstand extreme pressure conditions. After six months of field testing across 12 different sites, zero failures were reported. Their technical team worked closely with our engineers to develop the perfect alloy composition. Delivery was consistently on schedule across multiple orders totaling 50,000+ units.

As an industrial equipment importer serving European markets, quality certification is critical. QZSD’s documentation package exceeds our requirements, with comprehensive material testing reports for each batch. Their custom bearing assemblies reduced our assembly time by 22% while maintaining strict dimensional tolerances of ±0.01mm. Reliability has been outstanding across our 15,000 unit order.

The specialized bronze bushings QZSD manufactured for our marine equipment operate flawlessly in saltwater environments. After switching to their custom solutions, maintenance intervals increased from 6 months to 18 months. Their engineering team suggested a proprietary surface treatment that significantly improved corrosion resistance while staying within our budget constraints.

We needed custom-threaded nuts for a specialized agricultural machinery line with extremely tight deadlines. QZSD delivered 8,000 precision components two weeks ahead of schedule, with 100% quality compliance. Their technical support during implementation solved installation challenges we hadn’t anticipated. Three years later, we haven’t had a single field failure.

QZSD’s custom bearing solutions for our textile machinery reduced operational noise by 15 decibels while extending maintenance intervals. Their engineering team analyzed our specific requirements and recommended a hybrid ceramic design that outperformed expectations. Despite complex specifications, they maintained consistent quality across our order of 12,500 units over multiple shipments.

Contact Us

Get in touch with our responsive team to discuss your requirements for precision parts, request quotes or arrange factory visits. Contact us via our convenient channels for prompt, professional assistance.

Ready to discuss your machinery parts needs?

Our responsive team is here to help with custom solutions, quotes, and technical support. Fill out the form below or use our direct contact information to start a conversation about your specific requirements.